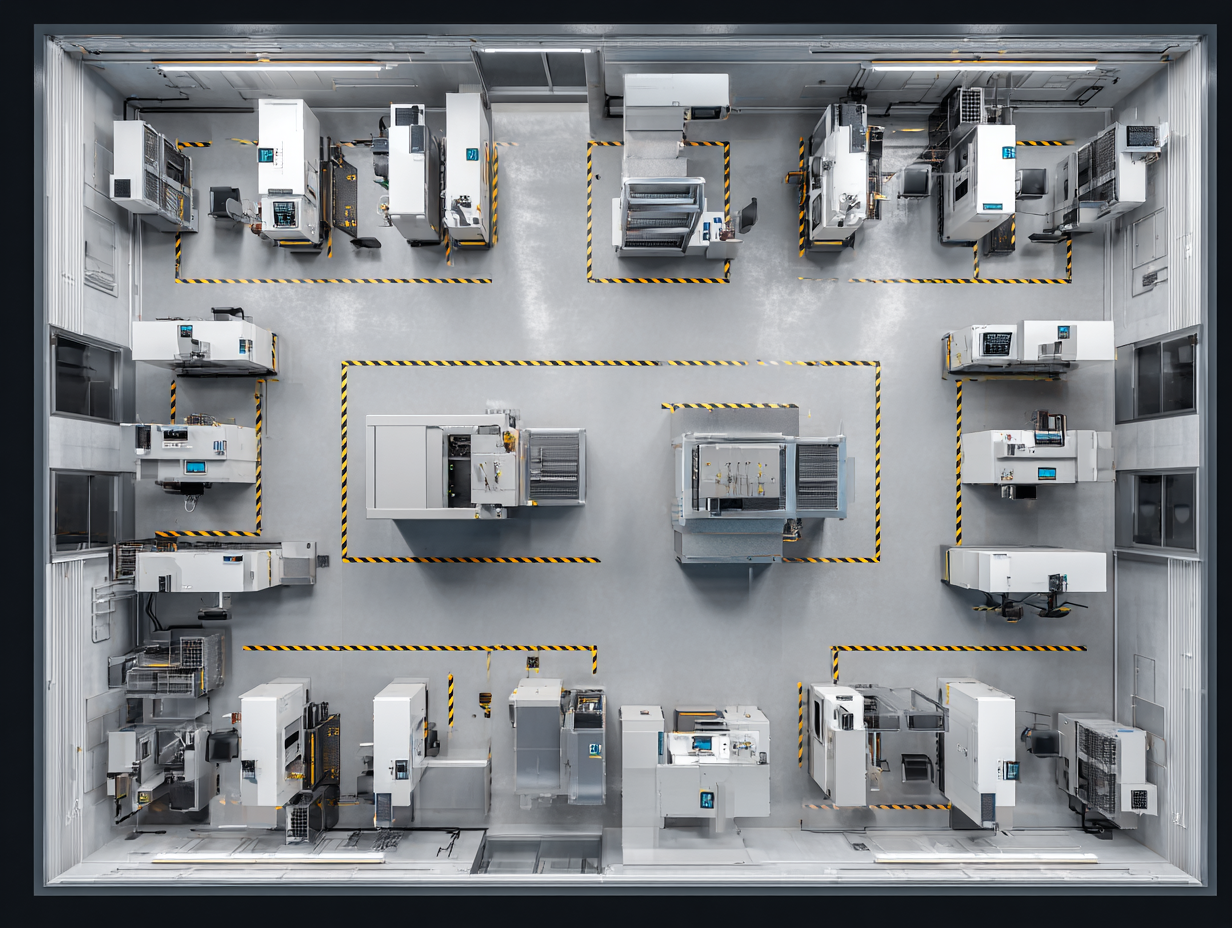

Equipment Room Soundproofing in NYC

Equipment rooms keep buildings running. They also generate some of the most persistent noise problems in commercial and residential properties. Generators hum around the clock. HVAC systems push vibrations through concrete and steel. Pumps cycle on and off, sending low-frequency rumble into offices, apartments, and workspaces that were never designed to handle it. At New York Soundproofing, we specialize in equipment room soundproofing that controls both airborne noise and structure-borne vibrations at the source. Our team has been engineering acoustic solutions for commercial facilities across NYC since 2002. We understand the unique challenges these spaces present, and we build systems that solve them without restricting access to your equipment or compromising ventilation.

Why Equipment Rooms Create Serious Noise Problems

Mechanical rooms, plant rooms, and utility spaces house the infrastructure that keeps a building operational. The problem is that this infrastructure never stops making noise. And that noise doesn't stay where it belongs.

Airborne Noise: HVAC Hum, Generator Roar, and Electrical Whine

Air handlers, compressors, and cooling towers produce constant broadband noise that penetrates standard walls and ceilings with ease. Generators add intense low-frequency energy during operation. Transformers and UPS systems contribute a high-pitched electrical whine that may seem minor in the equipment room itself but becomes maddening for people working or living on the other side of a wall. Without proper equipment room noise control, these sounds compound into a relentless background that erodes concentration and comfort throughout the building.

Structure-Borne Vibrations That Travel Through the Building

This is where equipment rooms differ from almost every other soundproofing challenge. Heavy rotating machinery doesn't just make sound. It shakes the floor, and those vibrations travel through the building structure far beyond the room itself. Tenants three floors up can feel the boiler cycling. Residents across the hallway can hear a pump they've never seen. Structure-borne noise is often felt as much as heard, and it requires a completely different approach than standard acoustic treatment. Absorption panels won't touch it. Only the physical decoupling of the equipment from the building stops vibrations from spreading.

OSHA Compliance and NYC Noise Code Requirements

Noise from equipment rooms isn't just an annoyance. It's a regulatory issue. OSHA sets workplace noise exposure limits at 85 dBA over an eight-hour shift. NYC enforces its own noise code with decibel restrictions that apply to commercial properties around the clock. Healthcare and educational facilities face even stricter standards. Failing to meet these requirements puts your building at risk of fines, complaints, and forced remediation. Professional noise and vibration control addresses compliance from day one, with documented results you can present during any inspection.

Our Equipment Room Soundproofing Services

Every equipment room has its own combination of machinery, construction type, and surrounding spaces. We design solutions that target your specific noise sources without limiting operational access or airflow.

Wall and Ceiling Sound Isolation

Walls and ceilings are the primary paths for airborne noise escaping equipment rooms. We reinforce them using Mass Loaded Vinyl, multiple layers of specialized drywall, damping compounds, and resilient channel systems that decouple surfaces from the building frame. These treatments dramatically increase the STC rating of your walls, blocking the hum, roar, and whine that standard construction lets through. For rooms adjacent to occupied spaces, we often combine several methods into a layered assembly that handles the full frequency spectrum.

Vibration Isolation and Equipment Mounting

This is the most critical service for equipment rooms. We install spring isolators, neoprene pads, and inertia bases beneath heavy machinery to break the mechanical connection between the equipment and the building structure. Flexible connectors on piping and ductwork prevent vibrations from traveling through plumbing and HVAC lines. Proper vibration isolation doesn't just reduce noise. It also lowers mechanical stress on your equipment, which extends its operating life and reduces maintenance costs over time.

Floor Soundproofing and Floating Systems

Equipment rooms located above occupied spaces need serious floor treatment. We build floating floor systems that sit on resilient pads, creating a physical gap between the equipment surface and the structural slab below. Anti-vibration mats go under individual machines for targeted isolation. These treatments work together to stop impact energy from reaching the floors, walls, and ceilings of the spaces beneath. The people below notice the difference immediately.

Door and Access Point Sealing

Doors are the most common weak point in any equipment room sound isolation project. Standard hollow-core doors with unsealed frames leak noise freely. We replace them with solid-core acoustic doors fitted with precision perimeter seals and automatic door bottoms. Every gap gets addressed because sound finds every opening, no matter how small.

Ventilation and Ductwork Noise Control

Equipment rooms need airflow. Sealing a room airtight is never an option. We line ducts with sound-absorbing material and install baffles at strategic points to catch noise before it travels through the ventilation system into adjacent spaces. Flexible connectors between equipment and ductwork prevent mechanical vibrations from entering the HVAC distribution network. The result is effective ductwork noise reduction that maintains full ventilation performance.

Solutions by Equipment Type

Different machines create different problems. We match our approach to the specific equipment in your facility.

HVAC Systems and Air Handlers

The most common source of equipment room noise. Air handlers produce constant airborne sound while compressors and chillers add vibration. We combine wall isolation with spring mounts and duct treatment to control both simultaneously.

Generators and Backup Power Systems

Generators produce intense low-frequency noise during operation and send powerful vibrations into the building structure. We design acoustic enclosures with proper ventilation and exhaust management, paired with heavy-duty isolation mounts rated for the unit's weight and output.

Pumps, Motors, and Electrical Equipment

Water pumps and hydraulic systems generate cyclical noise and vibration that can carry through an entire building. Transformers add a persistent electrical hum. We use inertia bases for heavy pumps, isolation pads for smaller motors, and flexible pipe connectors that break the vibration path at every junction point.

Benefits of Professional Equipment Room Soundproofing

Controlling noise at the source protects people, assets, and your bottom line all at once.

Reduced Noise in Adjacent Workspaces and Residences

Employees concentrate better. Tenants stop complaining. Conference rooms next to mechanical spaces become usable again. The impact on daily operations is immediate and measurable.

Full Regulatory Compliance

Every project we deliver meets or exceeds OSHA workplace noise limits and NYC noise code requirements. We provide documented before-and-after measurements that satisfy building management and regulatory inspectors alike.

Extended Equipment Lifespan

Uncontrolled vibrations accelerate wear on bearings, seals, and mounting hardware. Proper vibration isolation systems reduce mechanical stress across every component, lowering maintenance costs and extending the operating life of expensive equipment.

Why Choose New York Soundproofing

Our team brings over 20 years of commercial and industrial experience to every project. We have completed equipment room treatments in office towers, residential complexes, healthcare facilities, and mixed-use developments across all five boroughs. Every acoustic product we use is manufactured in-house at our Brooklyn facility, giving us full control over quality, customization, and lead times. Organizations like YouTube, Sony, The Metropolitan Museum of Art, and the City of New York trust us with their acoustic environments. Your facility gets that same level of engineering and attention.

Our Equipment Room Soundproofing Process

We coordinate with your facility management team to minimize operational disruption. Every project follows four clear steps: professional noise assessment with sound mapping and frequency analysis, engineered solution design with STC and vibration isolation specifications, installation by our in-house crew on a schedule that works for your building, and post-installation testing with full documentation of results. Nothing proceeds without your sign-off at each stage.

Equipment Room Soundproofing Materials

We work with Mass Loaded Vinyl, resilient channels, spring isolators, neoprene pads, acoustic duct liners, damping compounds, and floating floor assemblies. Each material targets a specific noise or vibration pathway, and we combine them into integrated systems calibrated to your facility's exact requirements.

Schedule Your Free Equipment Room Acoustic Assessment

Your building deserves quiet that your tenants and employees can actually feel. Call us at (877) 999-2201 or fill out our contact form to book a free, no-obligation assessment.

📞 Call (877) 999-2201 | Request Your Free Consultation

In this video New York Soundproofing demonstrates the dramatic difference before - and after - installing our acoustic panels. This acoustic treatment project was at the Galaxy Visuals video studio - a state-of-the-art video studio in Brooklyn, NY.

The video room was turned from acoustically unusable to sounding exceptional!

When our clients moved into the space, there was so much echo they couldn't do any video shoots with decent sound, or even understand each other speak.

New York Soundproofing to the rescue! We installed acoustic panels that matched the space and could fit in an area that is outside of the camera frame for a fantastic result. This is only one example of many where we transform an unusable space into a great-sounding room fit for recording, listening and more.

Contact us today to see how we can help transform your space! (Also see Galaxy's client testimonial video below).